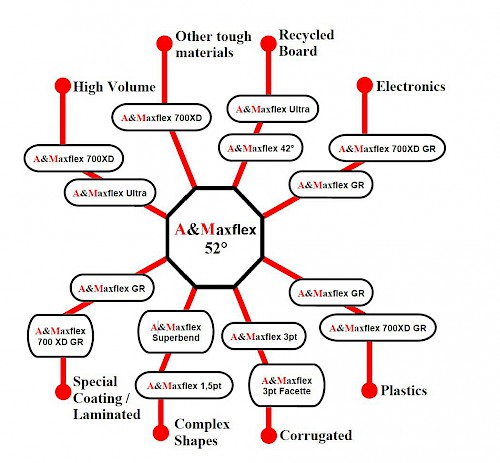

Cutting-Rules application Spider

Cutting rules

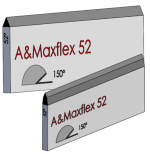

A&Maxflex 52

A&Maxflex 52

The A&Maxflex rule has a 52° cutting edge. The ideal combination of edge hardness and flexibility for

die-cutting a wide range of materials. The well controlled decarburisation allows a 2 point rule to bend

to a minimum of 150°.

Applications: For solid and corrugated boards and all commonly used substrates.

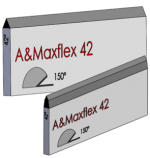

A&Maxflex 42

A&Maxflex 42

The 42° angle requires less cutting pressure which leads to a longer cutting life. The sharp cutting angle achieves easier penetration of the substrate, thereby reducing slivers, swarfs and dust. A 2 point rule can be bent to a minimum of 150°.

Applications: Particularly suited for paper boards and recycled boards with a high dust content.

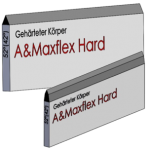

A&Maxflex Hard

A&Maxflex Hard

Comes with all the A&Maxflex features, but with a harder body. It is ideal for dies that require less tight bends, but where greater body stability is essential. The A&Maxflex Hard will stand up to the toughest of substrates.

Applications: Suited for solid and corrugated boards, plastics and dense substrates.

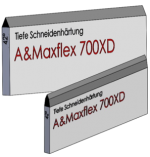

A&Maxflex 700XD

A&Maxflex 700XD

The 42° angle with deep edge hardening gives increased wear resistance. The edge hardness is 50% as deep as the A&Maxflex rule, significantly increasing die life on most applications.

Applications: For cutting abrasive materials such as gaskets and plastics.

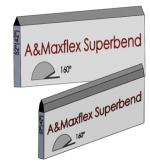

A&Maxflex Superbend

A&Maxflex Superbend

A slightly lower edge and body hardness gives greater bendability – up to 160°. A&Maxflex Superbend is the ideal rule for the production of more complex shaped dies.

Applications: Particularly suitable for greeting cards, tickets and presentation work.

A&Maxflex GR

A&Maxflex GR

Comes with all the A&Maxflex features, but with a harder body. The A&Maxflex has a course surface finish on the edge, resulting in micro-teeth along the edge. These micro-teeth along with the smaller edge radius make it much sharper than the shaved edge.

Applications: Cutting materials such as plastics, plastic laminated boards and other difficult substrates.

A&Maxflex Ultra

A&Maxflex Ultra

Comes with all the A&Maxflex features, but with a harder body. Available with both 42° and 52° edge.

It as a friction reducing coating. The cutting edge remains sharper longer. Gives considerable make-ready advantages, avoids costly downtime and reduces slivers and dust.

Edge configurations:

- Center Bevel

- Side Bevel

- Long Center Bevel

- Long Side Bevel

Creasing Rules

A&Maxflex Creasing Rules

A&Maxflex Creasing Rules

A&Maxflex Cut Crease

A&Maxflex Cut Crease

Using special tooling to eliminate burrs on the crease height to achieve aciean edge. It is available in any cut and crease height where there is a requirement for the box work to fold easily. It is also used as reverse crease, aiding the reduction of material stress.

Applications: Close ratio creasing e.g. gulleys.

A&Maxflex Hand Hole Perforating

A&Maxflex Hand Hole Perforating

This rule is available in left and right hand configurations to create top or side access panels. Special hand hole perforating rules can also be manufactured to customers with specific requirements. High precision rules made from edge hardened steel.

Applications: Where fast, easy access to the product is required, for example shelf ready packaging (SRP) or point of sale packaging (POS). Other applications include i.e. tissue boxes, confectionery boxes and tea bag cartons.

A&Maxflex Glue Flap Perforation

A&Maxflex Glue Flap Perforation

Applications: Glue flap panels.

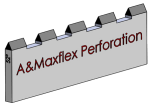

A&Maxflex Perforation

A&Maxflex Perforation

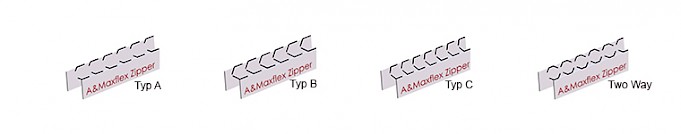

A&Maxflex Zipper

A high precision rule made from edge hardened steel, which is precisely manufactured with accurate pitches, constant slit depth and dean edges to avoid any 'drag'. The different asymmetrical shapes shown on the right are used in a left and right hand combination.

There are three standard zipper rules, type A, B and C. A two way symmetrical alternative eliminates the need for left and right versions. By varying the required length ratios indicated on the right, different configurations can be achieved.

Applications: Used to create a tear strip on cartons to access the product.

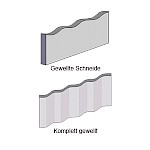

A&Maxflex Wave Rules

A&Maxflex Wave Rules

Edge hardened wave rules offer excellent bendability and high wear resistance. Special Wave Rules can be produced to customer's specific requirements.

Applications: For better creasing in corrugated and fibre boards.