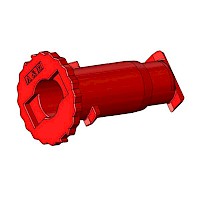

TrimSaver2 system

TrimSaver® applies pressure to the whole surface of the trim area and blocks any gap in which small waste can get stuck.

The system’s design provides a powerful ejection to strip away waste on even the smallest trim sizes. This advanced 3-step process of pressuring, blocking and ejecting provides advanced control and results in a perfect cut every time.

The system’s superior performance can save up to 66% on trim waste by reducing the total sheet size by an average of 2%. Because of its superior control, the TrimSaver® system can work with reduced trim of as little as ⅜” lead and trail edge total trim and ¼” total side trim.

TrimSaver® 2 improves the system’s performance on the lead edge, using a wider and more dynamic profile combined to a precisely calibrated motion.

Features & benefits

- Less operational downtime:

Reduced trim accumulation and improved durability keeps your machine moving. - Reduced die-cutting pressure:

Lower pressure and lead edge impact reduces anvil cover wear as well as stress on both die and machine. - Increased production speed:

Improved trim waste control and powerful ejection enables faster converting. - Reduced sheet sizes:

Requires less trim and smaller sheets. - Positive environmental impact:

Lower rates of paper consumption, less water and energy usage, and reduced waste.

How it works

It involves a 3-step process for perfect control and a perfect cut, bump after bump:

1. Pressuring:

Pressure is applied on the whole surface of the trim area against the anvil.

2. Blocking:

The combination of its high-tech features, block any gap in which the small trim can get stuck.

3. Ejecting:

Powerful ejection is supplied to push trim waste further downward even on the smallest sizes.

TrimSaver® Animation

This animation shows the 3-step process (pressuring, blocking and ejecting). Please note that there is a short pause between each step.