The Art of Die Making!

A&M visited Die – Techs (Alliance Group) in Seattle to consult and prepare for the future... As times are changing are we also seeing that the raw materials are changing, machines are getting more sophisticated and faster, yet, are we seeing that most of the dies are still made in the same way and manner. As nothing is wrong in doing it the traditional way, should one adapt new technics and improve the quality of rubber and look into the future.

As the Box Making machines run faster and raw materials have more recycling materials and to top it off are the glue ratios getting more, is the question if the rubbers on the market are still up to the task. And if yes, for how long?

The Challenge:

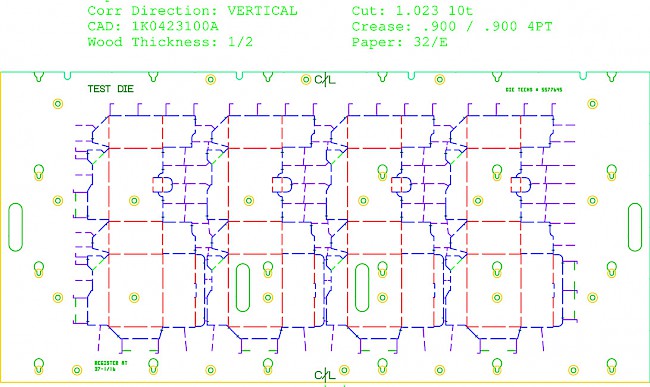

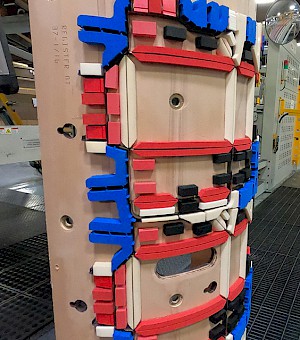

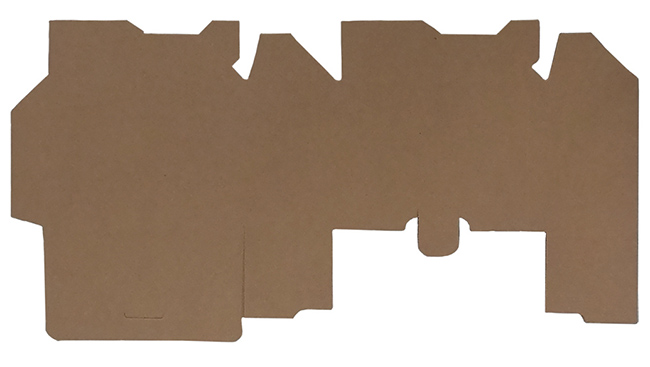

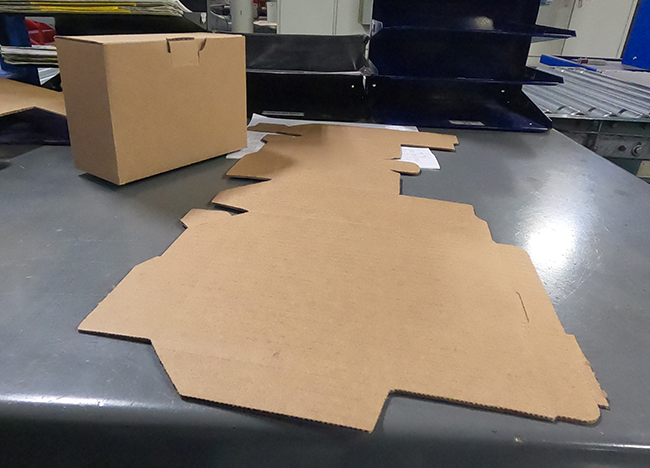

A 66 inch rotary die that should run on an Ward ServoGrafix machine. B-Wave, Cross Corrugated, Highly complicated, long runner with a wish for higher speeds.

When this job was made with conventional rubbers and with the standard and known heights, did several problems arise: Cracking, warping, crushing, non-ejecting trim causing bursts and marks.

The Solution:

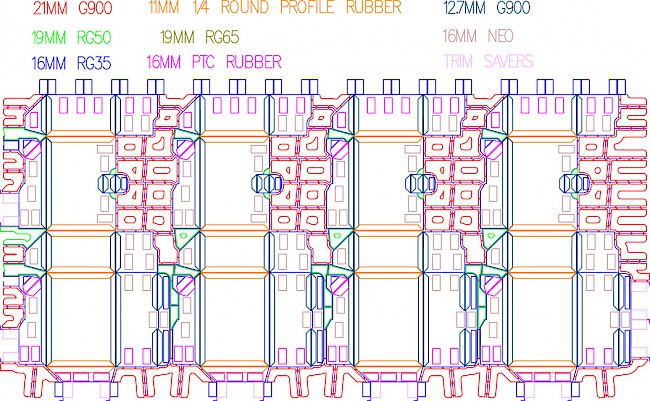

Part list:

1. Rubber:

G900

1.1 83-18-210 (21 mm)

1.2 83-18-190 (19 mm)

1.3 83-18-127 (12,7 mm)

Cellpolyurethane

1.4 86-50-190/D15 (19 mm / RG 50)

1.5 86-35-160/D15 (16 mm / RG 35)

1.6 86-65-190/D15 (19 mm / RG 65)

1.7 86-35-110/110P00

(11x11 mm Profiles / RG35)

PTC in 16 mm / 25 shore A

1.8 86-PTC-25-160

A&M Neo

1.9 83-17-160/H (16 mm)

2. Parts used on Die

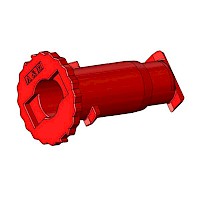

2.1 51-00-060 Powerlock

2.2 51-00-025 Drive in Washer

2.3 51-00-050 Fixing Part for Rules

2.4 Trimsaver

2.5 88-10-050 Powerglue

2.6 50-SO-026 Premium Mallet

2.7 20-00-007 T-Nut

2.8 10-00-011 Location washers

The result:

Speaks for itself!

The whole Story:

The Crew:

|

Justin Hennings

|

|

|

|

Sebastian Nowak

|

Rene Geyer Consulting & Interview A&M Stanzformzubehör  |